Terpene infusion has evolved from a being stopgap remedy for dried-out cannabis to a sophisticated production technique employed by leading cultivators and brands. Enhancing, restoring, or completely transforming flower profiles through targeted terpene application is a significant innovation in post-harvest cannabis processing.

Terpene infusion creates consistent sensory experiences, extends product shelf life, and elevates mid-tier biomass to premium products. Unlike DIY approaches that rely on citrus peels or kitchen spray bottles, commercial-grade terpene infusion leverages methodical application protocols, moisture-activity management, and specialized equipment to achieve dispensary-ready results.

This comprehensive guide walks product developers, cultivation teams, and brand managers through the science-based techniques that ensure even distribution, proper absorption, and authenticity in terpene-enhanced flower products.

Key Takeaways

- Terpene infusion is now a precision-based, commercial strategy to enhance cannabis flower quality, improve consistency, and elevate product positioning.

- Moisture control is critical, with an optimal relative humidity (RH) range of 58–62%, for effective terpene absorption, preventing microbial risks, and preserving product integrity.

- A structured, three-phase infusion protocol ensures even terpene distribution, maximizes retention, and guarantees premium sensory outcomes.

- Proper environmental and equipment controls (e.g., temperature, airflow, and infusion methods (tumbling systems, NEU Bags, or spray techniques)) are essential to avoid terpene degradation and achieve desired flavor profiles.

A Closer Look at Effective Terpene Infusion

Before exploring specific protocols, it is vital to understand the fundamental mechanisms that govern successful terpene infusion in cannabis flower.

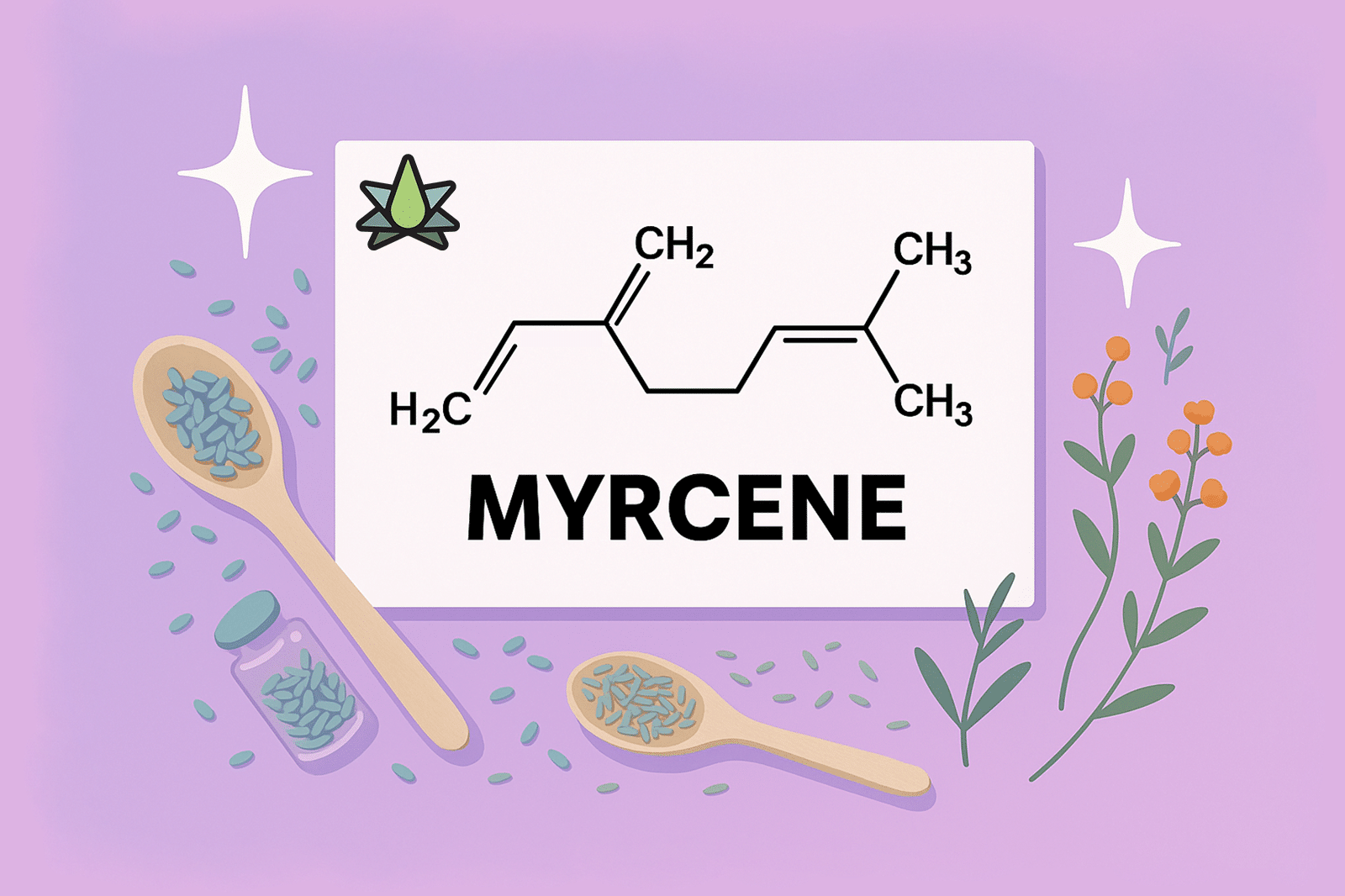

Terpenes are volatile, lipophilic compounds that interact with plant material in complex ways determined by molecular weight, polarity, and the physical structure of cannabis. The goal of any infusion process is to achieve homogenous distribution without damaging trichomes, creating “hot spots,” or introducing unwanted moisture that could compromise stability.

Flower moisture content of 10-12% helps preserve terpene content in cannabis, directly enhancing the product’s flavor profile. This relationship between humidity and terpene preservation underscores the importance of proper moisture management throughout the infusion process.

The primary challenges facing commercial producers include moisture balance, distribution uniformity, terpene retention, and sensory integration. Achieving the right balance of these factors is critical for successful terpene infusion that results in premium cannabis products that maintain their quality over time.

Cannabis contains over 150 different terpenes and terpenoids in cannabis, highlighting the complexity of these aromatic compounds and their potential contribution to the overall cannabis experience. Understanding this diversity is crucial when selecting specific terpene profiles for infusion projects.

| Ambient Moisture Level | Effect on Terpene Infusion | Application Recommendation |

| Below 55% RH | Poor absorption, oil pooling, uneven distribution | Precondition with humidity packs for 24-48 hours before infusion |

| 55-65% RH | Optimal absorption and integration | Proceed with the standard infusion protocol |

| Above 65% RH | Excessive moisture, increased microbial risk | Allow controlled evaporation to the target range before infusion |

There are many ways to infuse terpenes, including NEU Bags, direct spray application, and automated tumbling systems, but all successful approaches follow these fundamental phases.

Terpene Selection and Quality Impact

The source and quality of terpenes used in flower infusion dramatically influence the final result. Understanding the differences between cannabis-derived and botanical terpenes is essential for making informed product decisions. Commercial infusion operations should evaluate terpenes based on:

- Extraction Method: Steam-distilled terpenes maintain the highest integrity of delicate compounds compared to solvent-extracted alternatives.

- Purity Testing: COA-verified terpenes free from residual solvents, diluents, or artificial carriers ensure consistent results and regulatory compliance.

- Terpene Profile Complexity: Full-spectrum terpene profiles containing 30+ compounds provide more authentic cannabis experiences than blends of 5-10 isolated terpenes.

Our All Flavor Profile Oils Sampler offers an ideal starting point for experimenting. It contains categorized flavor profiles representing the prominent cannabis terpene families. This allows producers to test different profiles before committing to full-scale production.

Three-Phase Protocol for Commercial Terpene Infusion

Successful terpene infusion follows a structured three-phase process developed through years of application testing. This protocol scales effectively from small-batch operations to industrial production volumes while maintaining high-quality standards.

Phase 1: Preparation and Moisture Equilibration

Proper flower preparation is the foundation of successful terpene infusion. Inconsistent moisture content is the most common cause of infusion failure in commercial operations, resulting in uneven terpene distribution and unpredictable sensory outcomes.

Proper packaging and preservation methods can significantly alter terpene profiles in cannabis flower. Depleted terpene profiles could be successfully replenished through controlled infusion, with some samples achieving as much as 95% concentration of terpenes when properly managed.

Step 1: Moisture Testing and Conditioning

Before infusion, moisture analysis should be conducted using a calibrated moisture activity meter. Water activity (the ratio of vapor pressure in the flower to pure water at the same temperature) provides a more precise measurement than simple moisture content, as it indicates how water is bound to the plant’s molecules, directly affecting terpene absorption.

For optimal results, flower should have between 58-62% RH. According to cultivation experts, this range provides the ideal environment for terpene integration without promoting microbial growth. Flower testing outside this range requires conditioning through the following methods:

- For overly dry material (below 55% RH): Place the flower in a controlled humidification chamber with humidity packs at 62% RH for 24-48 hours, depending on initial dryness. Monitor periodically until the target range is achieved.

- For overly moist material (above 65% RH): Allow controlled evaporation in a low-humidity environment (40-45% RH) with gentle air circulation. Avoid rapid drying, which can damage trichomes and compromise terpene receptivity.

Step 2: Surface Preparation and Environment Control

The physical arrangement of the flower before infusion impacts distribution quality. To expose maximum surface area without damaging the flower structure, break down large clusters, arrange material in shallow layers no more than 1 inch deep, and use food-grade surfaces.

Recommended environmental conditions during preparation:

| Environmental Factor | Recommended Range | Reason |

| Temperature | 65-70°F (18-21°C) | Prevents excessive terpene volatilization while allowing absorption |

| Ambient Humidity | 55-65% relative humidity | Creates an appropriate gradient for moisture balance |

| Air Flow | Minimal but sufficient | Prevents stagnant air pockets without accelerating terpene loss |

| Light Exposure | Minimal, no direct UV | Reduces the photodegradation of sensitive terpene compounds |

The preparation phase typically requires 24-48 hours, depending on the initial condition of the flower. Investing in proper conditioning pays dividends in final product quality and consistency.

Phase 2: Precision Application Techniques

With properly conditioned flower, the application phase requires careful attention to dosing, distribution methodology, and temperature management to achieve professional results. Several commercially viable methods, from NEU Bag infusion packs to direct application techniques, can be used, as described below.

Step 1: Terpene Selection and Dosage Calculation

The infusion ratio acutely determines a finished product’s sensory impact and economic parameters. Based on extensive commercial production data and laboratory testing, we recommend the following dosage guidelines:

| Enhancement Level | Dosage Range (w/w) | Application | Results |

| Light Enhancement | 0.5-0.8% | Refreshing slightly aged flower | Subtle restoration while maintaining strain identity |

| Standard Enhancement | 0.8-1.2% | Mid-tier flower enhancement | Noticeable sensory impact complementing existing terpenes |

| Premium Transformation | 1.2-2.0% | White-labeling, signature varieties | Complete profile reconstruction with distinctive character |

The calculation formula is:

Terpene amount (g) = Flower weight (g) × Desired concentration percentage (%) ÷ 100

For example, to achieve a 1% terpene concentration in 1,000g of flower:

1,000g × 1% ÷ 100 = 10g terpenes

Step 2: Application Methodology

The application technique significantly impacts distribution quality. Depending on the production scale and requirements, three primary methods are commonly used in commercial settings:

- Precision Dropper Method: Best for small-batch production (under 1kg), using calibrated dropper systems for direct application to flower in thin, distributed layers with multiple passes. While time-intensive, this method provides excellent control for premium small-batch production.

- Volumetric Spray Application: Suits medium-scale production (1-5kg) using pharmaceutical-grade ultrafine mist sprayers with 100-120 micron droplet size. To ensure coverage uniformity, the application should occur 12-15 inches from the flower surface in multiple light passes with a systematic movement pattern.

- Tumble Infusion System: Serves large-scale production (5 kg+) with specialized tumbling equipment featuring precision dosing systems, gentle rotation with programmable speed control, and adjustable infusion cycles based on material density. This method offers the highest efficiency for commercial volumes.

- NEU Bag Diffusion: A new technology that uses terpene-saturated mesh bags placed directly with the flower in sealed containers. This method leverages natural diffusion principles to migrate terpenes from the specialized bag to the flower over 48 hours. It is suitable for simplified workflows without substantial equipment investment.

For temperature considerations during application, maintain controlled environments at 65-70°F (18-21°C). Application at higher temperatures increases volatilization and terpene loss, while colder environments reduce absorption efficiency. Most cannabis terpenes begin to degrade at temperatures above 70°F, making precise temperature control essential for preserving the complete terpene profile.

Step 3: Initial Distribution

Immediately following application, gently mix or tumble the material to promote initial distribution. Avoid aggressive handling that could damage trichomes. Inspect for consistent appearance without obvious concentration areas before transferring to appropriate curing containers within 10 minutes of application.

The application phase typically requires 15-45 minutes per kilogram of material for direct application methods, or 48 hours with NEU Bag systems.

Phase 3: Absorption and Stabilization

The final phase allows terpenes to fully integrate with the flower while stabilizing moisture content for long-term product integrity. Proper absorption and stabilization are critical for preserving terpenes, which are highly volatile and can easily evaporate if not properly integrated into the plant material.

Step 1: Primary Absorption Period

After application, the infused material requires a controlled environment for initial terpene integration. Temperature, light exposure, and oxygen levels significantly impact terpene stability during this critical phase.

Transfer the material to breathable, food-grade containers (specialized options like NEU Bags work well for this purpose). Through appropriate container selection, maintain the environment at 62-65°F (16-18°C) in darkness with 58-62% RH.

Allow 12-24 hours of undisturbed rest for the terpenes to penetrate the flower structure and begin bonding with existing compounds and plant lipids.

Generally, terpenes bond differently with various plant structures. Some integrate more readily with plant lipids, while others interact with existing terpenes through molecular attraction.

Step 2: Controlled Burping and Equilibration

Following initial absorption, an equilibration process helps achieve uniform distribution and prevents pressure buildup from volatile compounds while allowing moisture to distribute evenly throughout the product.

| Time Point | Action | Purpose |

| 12-24 hours after application | Briefly open containers | Release accumulated volatile compounds and exchange air |

| During opening | Visual inspection | Check for uniform appearance and consistent moisture |

| After inspection | Return to the controlled environment | Continue the absorption process |

| 24-48 hours after application | Repeat the burping process | Final equilibration before packaging |

Controlled burping can increase terpene retention by 15-20% compared to sealed storage methods without air exchange. The periodic release of accumulated gases prevents pressure that could force volatile terpenes out of the plant material.

Step 3: Quality Assessment

Before final packaging, conduct a comprehensive quality assessment protocol that combines analytical and sensory evaluation:

Visual inspection should verify consistent appearance without oil pooling, while olfactory assessment confirms balanced terpene expression without artificial or chemical notes. Moisture testing using calibrated equipment should confirm the product remains in the 58-62% RH range for optimal stability.

Physical handling helps verify proper texture without stickiness or dryness, and test burn or vaporization provides critical data on flavor translation and smoke/vapor quality. Maintaining detailed records of these quality parameters creates valuable baseline data for continuous improvement.

The stabilization phase typically requires 24-72 hours, depending on batch size and specific terpene profiles. While this may seem time-intensive, rushed curing after terpene application can result in the loss of volatile compounds, particularly monoterpenes that contribute significantly to desired flavors and effects.

Terpene Selection for Optimal Results

The quality and type of terpenes used determine infusion success. Given that cannabis contains different terpenes and terpenoids, understanding the differences between terpene categories is essential for selecting the right inputs.

Terpene Source Comparison

| Terpene Source | Authenticity | Complexity | Cost Range | Best Applications |

| Cannabis-Derived Terpenes | Highest | 150+ compounds | $30-80/gram | Premium flower, connoisseur products |

| Enhanced Natural Terpenes | Medium-High | 30-60 compounds | $15-40/gram | Mid-tier products, white label development |

| Botanical Terpenes | Low-Medium | 10-30 compounds | $5-15/gram | Mass market products, cost-sensitive applications |

Cannabis-Derived Terpenes (CDT)

Native Cannabis Terpenes provide the most authentic sensory experience with complete terpene profiles. These premium inputs feature full-spectrum profiles with terpene diversity, including minor compounds that contribute to the entourage effect. They also deliver authentic cannabis aroma and integrate well with cannabis material.

Terpene profiles have a unique “fingerprint” of major and minor compounds that create their distinctive character. This complexity is difficult to replicate through botanical blending. Consequently, cannabis-derived terpenes from trusted sources are the optimal choice, despite higher procurement costs, for premium flower products going for authenticity and quality.

Our Fresh Never Frozen® Sample Kits are excellent for evaluating different terpene profiles before scaling to production quantities.

Enhanced Natural Terpenes

Specialized blends combine cannabis-derived compounds with selected botanical terpenes to create specific sensory profiles. They provide terpene diversity and maintain consistency across production batches. Their enhanced stability in various applications makes them cost-effective for scaling mid-tier products.

According to formulation experts, enhanced natural terpenes work well for white-label products and house brand development, where distinctive, proprietary aromas are desired. They strike a balance between authenticity and production economics.

Botanical Terpenes

Botanical terpenes (derived from non-cannabis plant sources) are the most economical option but require careful selection and blending. While they present a higher risk of “off-notes” if not properly formulated, they are appropriate for mass-market applications focusing on price.

However, botanical terpenes integrate less with cannabis compounds, often creating a sensory disconnect between smell and taste. They are also more unstable during the infusion. While botanical options may suit large-scale production economics, they require deep technical expertise to implement successfully without compromising product authenticity.

Testing and Sampling Strategies

Implement a structured testing protocol before scaling to full production to identify the optimal parameters for your specific material, equipment, and quality goals. Our sample kits allow you to evaluate multiple profiles with minimal investment.

Structured Testing Protocol

A comprehensive sampling approach should include analytical and sensory evaluation components.

| Testing Component | Method | Metrics to Record |

| Batch Preparation | Create 50-100g test batches with 3-5 different terpene percentages | Initial moisture content, terpene concentration, and application method |

| Environmental Documentation | Record all parameters during testing | Temperature, humidity, application time, and curing duration |

| Sensory Evaluation | Conduct blind testing with trained staff | Aroma profile, flavor notes, smoothness, and effect onset |

| Temporal Assessment | Test at multiple cure durations | Profile development at 24h, 72h, 7 days, 14 days |

| Technical Performance | Evaluate consumption characteristics | Burn quality, ash color, vapor production, flavor transition |

This systematic approach identifies optimal parameters for the material and equipment before committing to full-scale production.

Scaling Your Infusion Operation

A methodical, staged approach ensures quality for producers seeking to establish or expand their terpene infusion capabilities. The journey from initial experimentation to full commercial implementation requires careful planning and systematic capability development to maintain product integrity throughout scaling.

Experimentation & Validation Stage

Begin the infusion program with an experimentation phase to identify optimal profiles and refine protocols for your specific operation.

Key Activities:

- Implement the NEU Bag protocol at smaller scales (1-2 ounces per test)

- Evaluate different profiles across multiple flower varieties

- Create structured feedback mechanisms for sensory impressions and technical metrics

- Identify 2-3 winning terpene profiles for scaled production

To better understand the range of available options, get more insights on terpene-rich cannabis strains.

Small Batch Production Development

Once done with the experiment phase, proceed to small batch production that processes 1-2 pounds per batch using the selected profiles. This stage is a crucial proving ground for developing formal Standard Operating Procedures (SOPs) that document every aspect of your infusion protocol.

Key Activities:

- Process 1-2 pounds per batch using selected profiles

- Develop comprehensive documentation of your entire workflow

- Establish formal quality metrics and testing protocols

- Train production staff on proper techniques

Commercial Scale Implementation

Infrastructure and workflow design are critical success factors in implementing terpene infusion at a full commercial scale. Design production workflows that integrate infusion into the post-harvest processing sequence, accounting for space requirements, labor allocation, and timeline impacts on downstream operations.

Key Activities:

- Design workflow for continuous production across larger volumes

- Implement batch tracking systems for process documentation

- Establish supplier relationships for consistent terpene access

- Create dedicated processing spaces with environmental controls

For operations ready to move into full commercial production, the Exclusive Oils Sampler provides signature blends formulated for premium product lines. These formulations create proprietary sensory experiences that stand out while delivering the consistency required for commercial-scale operations.

Review our recommendations on top terpene infusion solutions for a detailed guide on implementing terpene solutions for larger-scale operations.

Equipment Recommendations for Commercial Applications

Successful commercial-scale terpene infusion requires specific equipment matched to the production volume and quality standards. The right equipment significantly impacts consistency, efficiency, and final product quality.

Equipment Selection Guide by Production Scale

| Production Scale | Essential Equipment | Recommended Investment Level |

| Small Batch (<10 lbs/week) | Moisture meter, precision scale, droppers/pipettes, sealed containers | $500-1,500 |

| Medium Production (10-100 lbs/week) | Above, plus pharmaceutical sprayers, environmental monitoring, specialized containers | $2,000-7,500 |

| Large Scale (>100 lbs/week) | Complete environmental control systems, automated application equipment, and enterprise-quality tracking | $10,000-50,000 |

For entry-level operations, essential equipment includes calibrated moisture activity meters (0.5% accuracy minimum), laboratory-grade scales with 0.01g precision, stainless steel processing surfaces, temperature and humidity monitoring systems, and proper PPE including nitrile gloves and eye protection.

Operations scaling to higher volumes should consider pharmaceutical-grade spray equipment with adjustable parameters for more uniform application. NEU Bags provide an alternative approach requiring minimal equipment investment while delivering professional results.

Advanced operations can benefit from automated tumble infusion systems with precision dosing, environmental control chambers for preparation and curing, digital record-keeping systems for batch documentation, automated moisture analyzers for rapid testing, and sensory evaluation stations with proper lighting and ventilation.

While basic infusion can be accomplished with minimal investment, commercial consistency requires appropriate equipment scaled to production volume. The equipment selection should balance initial capital costs against long-term efficiency gains and quality improvements.

Troubleshooting Common Infusion Issues

Even with carefully designed protocols, terpene infusion occasionally encounters challenges that require systematic troubleshooting. Understanding the root causes of common issues enables producers to implement practical solutions to maintain product quality and consistency.

Uneven Terpene Distribution

When infused flower exhibits inconsistent aroma or flavor across the batch, the problem typically stems from insufficient rotation during the absorption phase or overpacked containers that prevent proper vapor distribution.

Solution Steps:

- Reduce batch size to ensure adequate space for vapor movement

- Implement additional rotation cycles (every 6-8 hours instead of every 12 hours)

- Use multiple smaller NEU Bags distributed throughout larger containers

- Allow longer homogenization periods after the primary absorption phase

Weak Terpene Expression

Underwhelming terpene expression often results from three primary factors:

- Insufficient moisture in the flower material

- Inadequate terpene concentration

- Premature packaging before full absorption completes

Solution Steps:

- Verify moisture content falls within the optimal 10-12% range

- Increase terpene concentration by 0.2-0.3% while staying below 1.5% total

- Extend the primary absorption period by 12-24 hours to allow more complete integration

- Confirm environmental conditions remain within recommended parameters

For more guidance on terpene preservation, our guide on how to preserve terpenes provides detailed information on maintaining terpene integrity throughout processing.

Harsh or Chemical Flavor Notes

The appearance of unpleasant flavor characteristics typically indicates excessive terpene concentration, poor-quality source materials, or inadequate stabilization time.

Solution Steps:

- Reduce terpene percentage to approximately 0.8% for milder integration

- Verify terpene source quality with comprehensive Certificates of Analysis

- Extend the final stabilization period to a full 24 hours

- Implement longer “breathing” periods after removing terpene sources

Excessive Moisture After Infusion

When infused flower has a higher moisture content than desired after the process completes, the issue usually stems from the starting material. It may mean that the flower was already at the high end of the acceptable range or improper temperature control occurred during absorption.

Solution Steps:

- Begin with 6-8% moisture content for materials prone to moisture retention

- Maintain temperature strictly below 70°F throughout the protocol

- Implement a longer stabilization period with gentle, controlled airflow

- Use slightly lower humidity control packs during final packaging

From our experience developing infusion protocols for commercial producers, implementing a systematic troubleshooting approach identifies and resolves most issues within a single production cycle. Detailed documentation of process variables helps identify patterns that can be addressed through procedure refinement rather than reactive troubleshooting.

Conclusion: The Future of Flower Enhancement

Terpene infusion represents an opportunity for cultivators and brands to differentiate their products through enhanced sensory experiences. Producers can achieve consistent, high-quality results that meet market expectations by implementing the professional-grade protocols outlined in this guide.

For operators seeking to explore terpene infusion, Terpene Belt Farms offers Terpene Sample Packs specifically for commercial flower enhancement. These kits include the necessary products, detailed protocols, and technical support to implement successful infusion programs at any scale.

Get started with our NEU Bag Flavor Sampler – the simplest way to implement commercial-grade terpene infusion without significant equipment investment or process complexity.

Frequently Asked Questions (FAQ)

What Is Terpene Infusion, and Why Is It Important for Cannabis Flower?

Terpene infusion is a post-harvest technique used to enhance, restore, or transform the aromatic profile of cannabis flower by applying terpenes directly. This process helps improve product consistency, shelf life, and sensory appeal.

What’s the Ideal Moisture Level for Successful Terpene Infusion?

The optimal relative humidity (RH) range is 55–65%. This moisture level allows for even terpene absorption while avoiding microbial risks and terpene loss. Flower outside this range should be conditioned using humidity packs (if too dry) or allowed to air dry (if too moist) before infusion.

What Methods Are Used For Terpene Infusion In Commercial Settings?

There are several methods depending on production scale, including:

- Precision droppers for small batches

- Volumetric mist spray for medium production

- Tumble infusion systems for large-scale operations

- NEU Bag diffusion, a no-equipment method using terpene-saturated mesh bags

How Can I Choose the Right Terpenes for Infusion?

Consider the source and complexity:

- Cannabis-derived terpenes offer the most authentic, full-spectrum profiles and are ideal for premium products.

- Enhanced natural terpenes balance cost and quality, suited for white-label or mid-tier products.

- Botanical terpenes are the most economical but less authentic and best for mass-market goods.

Sources Cited:

Brincker, J., Rose, J. et al. “The preservation and augmentation of volatile terpenes in cannabis inflorescence.” Journal of Cannabis Research, vol. 2, article 27, 2020. https://jcannabisresearch.biomedcentral.com/articles/10.1186/s42238-020-00035-z

Technology Networks. “Testing the Water: The Top Techniques for Moisture Content Analysis In Cannabis.” July 25, 2019. https://www.technologynetworks.com/applied-sciences/articles/testing-the-water-the-top-techniques-for-moisture-content-analysis-in-cannabis-390048