High Terpene Extract (HTE) is a specialized segment of cannabis concentrate that prioritizes the preservation of aromatic compounds over cannabinoid potency. For product developers and formulators entering the cannabis space, understanding HTE’s technical parameters, production methods, and appropriate applications provides critical context for formulation decisions.

This article breaks down the science behind HTE production, examines its advantages and limitations in commercial applications, and identifies scenarios where Terpene Belt Farms’ cannabis-derived terpenes (CDT) offer superior alternatives for product development.

Key Takeaways

- High Terpene Extract retains the complete aromatic profile of cannabis. It contrasts with high-cannabinoid extracts that focus on THC/CBD content.

- While HTE offers full-spectrum sensory experiences, its production requires careful control over extraction parameters. Challenges include high viscosity, short shelf life, regulatory hurdles, and inconsistency between batches.

- Cannabis-derived terpenes have the aromatic excellence of HTE without THC, offering benefits like better hardware compatibility, longer shelf stability, interstate compliance, and batch consistency.

- Due to their stability, CDTs are especially advantageous in vape, edible, and topical applications.

Origins and Technical Definition of HTE

HTE emerged from the pursuit of full-spectrum concentrates that preserve the complete sensory and effect profile of the original plant material. Unlike high-cannabinoid extracts that prioritize THC/CBD content, HTE aims for high terpene levels (15-25% by weight).

From a technical standpoint, HTE is defined by three primary characteristics:

- Terpene Concentration: Minimum 15% terpene content by weight

- Cannabinoid Profile: 45-65% total cannabinoids (compared to 70-95% in high-cannabinoid extracts)

- Physical Properties: Semi-viscous consistency at room temperature due to high terpene content

The development of HTE processing techniques is a significant technical evolution in cannabis extraction. Traditional extraction focuses primarily on cannabinoid recovery, often sacrificing volatile terpenes through aggressive solvent removal or high-temperature processing. HTE production, by contrast, employs specialized parameters to retain these heat-sensitive compounds.

At Terpene Belt Farms, we take terpene preservation a step further with our Fresh Never Frozen® technology, which maintains the complete terpene profile of Cannabis Sativa L. Our proprietary process captures more than 200 distinct compounds from cannabis.

The Science of HTE Production

The production of high-quality HTE requires precise technical controls throughout the extraction and post-processing workflow. Multiple methodologies exist, each with specific advantages and technical considerations:

Primary Extraction Methods

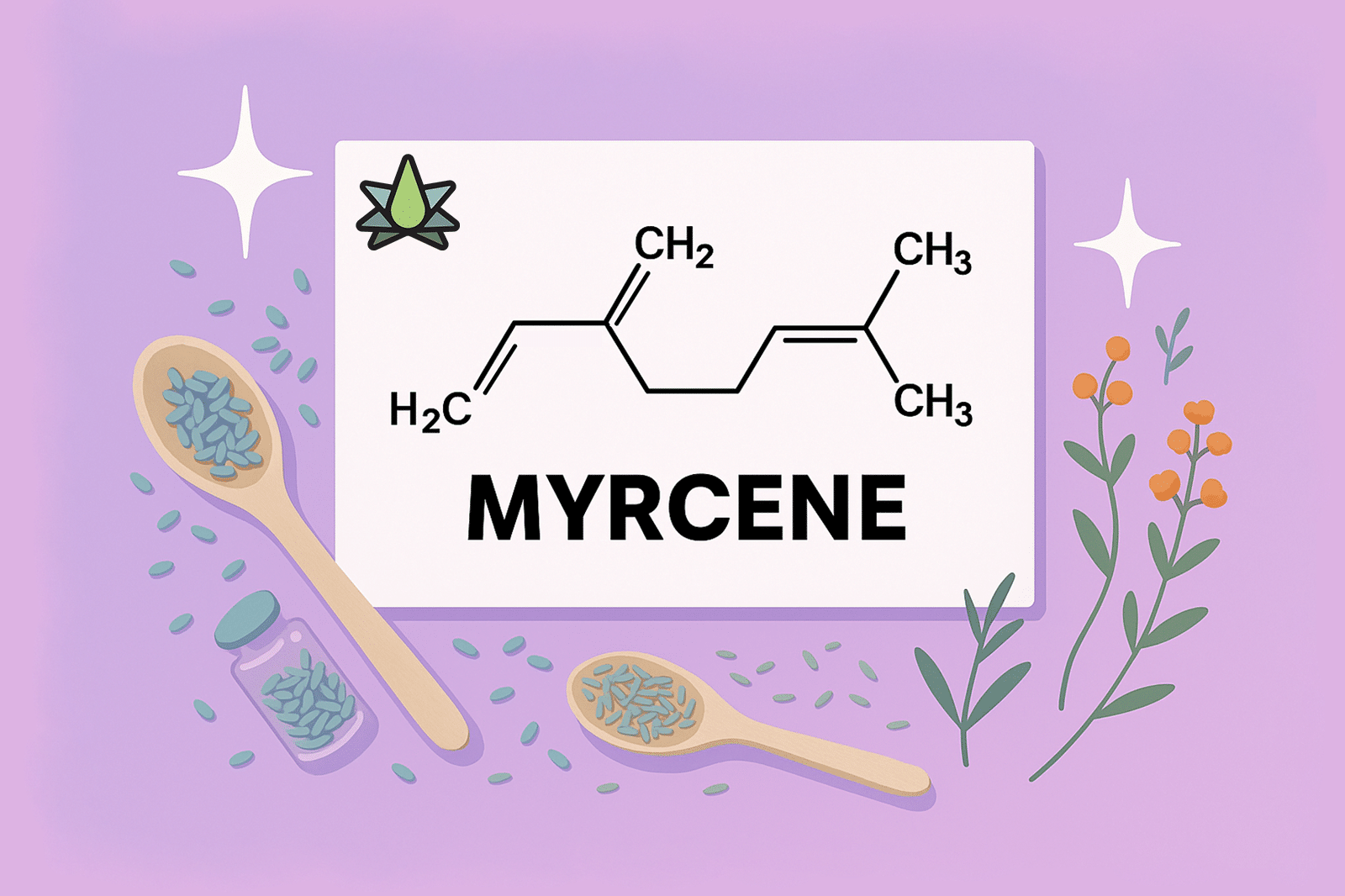

Hydrocarbon Extraction: The most common approach for commercial HTE production utilizes light hydrocarbons ( butane or propane) at sub-zero temperatures (-20°C to -50°C). This cold-processing method preserves temperature-sensitive monoterpenes like myrcene, limonene, and pinene that would otherwise degrade during extraction.

Supercritical CO₂: While less common for dedicated HTE production, modified CO₂ extraction with specialized fractionation can produce terpene-rich extracts. This method requires precise pressure and temperature control to capture terpene fractions before cannabinoid extraction.

Solventless Methods: Advanced techniques such as live rosin production through ice-water extraction followed by low-temperature pressing can produce solventless HTE, though typically with lower terpene concentrations (8-15%) than solvent-based methods.

Critical Processing Parameters

The technical distinction between HTE and standard extracts lies primarily in the post-extraction processing parameters:

| Processing Parameter | Standard Extract | HTE Production | Technical Rationale |

| Solvent Removal Temperature | 45-60°C | 25-35°C | Lower temperatures prevent terpene volatilization |

| Vacuum Pressure | 28-29.5 inHg | 20-25 inHg | Reduced vacuum prevents pulling terpenes with solvent |

| Processing Duration | 24-48 hours | 72-120 hours | Extended time compensates for gentler parameters |

| Winterization | Standard | Minimal/None | Preserves terpenes that would be lost in winterization |

Gentle processing methods preserve more cannabis native terpenes, while standard extraction methods typically retain only a fraction. At Terpene Belt Farms, our specialized extraction method consistently preserves the complete terpene profile, outperforming even the most advanced HTE production methods.

For product formulators, understanding these production parameters helps explain the significant cost differential between HTE and conventional extracts. The extended processing time, specialized equipment requirements, and lower overall yields directly impact production economics.

Types of High Terpene Extract

The HTE category encompasses several distinct product types, each with specific technical characteristics and formulation applications:

Strain-Specific HTE

Derived from single cannabis cultivars, strain-specific HTE preserves the exact terpene profile of the source material. These extracts typically exhibit 15-25% terpene content with cannabinoid concentrations of 50-65%. A strain-specific HTE has distinctive sensory characteristics and targeted effects based on the source.

For product developers, strain-specific HTE provides formulators with recognizable sensory profiles that align with established consumer expectations. However, batch-to-batch consistency can be challenging due to natural variations in cultivation conditions.

Terpene Belt Farms addresses this consistency challenge through our standardized terpenes, which deliver batch-to-batch consistency within ±2% variance for all major terpene components. Our profiles include authentic representations of market-leading strains like Gas#150 (OG strains), Fruit#132 (Cherry Bomb), and Purple#100 (Granddaddy Purple).

Blended HTE

Created by combining multiple extraction batches or different cultivars, blended HTE allows manufacturers to develop custom terpene profiles. This approach enables greater batch consistency and targeted effect formulation through intentional terpene ratio engineering.

From a technical perspective, blended HTE typically undergoes homogenization to ensure uniform distribution of terpenes and cannabinoids throughout the extract. Without proper homogenization, separation can occur during storage, creating inconsistent product performance.

Live Resin HTE

Distinguished by its starting material rather than processing methodology, live resin HTE utilizes fresh-frozen cannabis rather than dried and cured material. This preservation technique maintains higher concentrations of monoterpenes that would otherwise oxidize during drying and curing. Live resin HTE exhibits several technical distinctions:

- Higher monoterpene ratios

- Elevated levels of volatile compounds like terpinolene

- Unique sensory characteristics not found in extracts from dried material

- Typically requires cold-chain management throughout production

For formulators developing premium products, live resin HTE provides distinctive sensory profiles unattainable with conventional extracts. However, these benefits come with significant supply chain and processing complexities.

Thanks to our specialized processing method, our terpenes capture these same monoterpene-rich profiles. The result? Live resin-quality terpene profiles without the regulatory complications of THC-containing extracts.

Our vape formulation best practices guide provides specific recommendations for integrating these profiles into premium product lines.

Benefits and Limitations of HTE in Product Formulation

For formulators evaluating HTE as a potential ingredient, understanding its advantages and technical limitations is essential for effective product development.

Technical Advantages

HTE offers several significant benefits in product applications:

- Complete Sensory Profile: The full spectrum of terpenes creates authentic, complex aroma and flavor characteristics that differentiate products in competitive markets.

- Enhanced Effect Profiles: Research demonstrates that some terpenes can directly modulate cannabinoid receptor activity, enhancing therapeutic outcomes through the entourage effect.

- Product Differentiation: The distinct sensory characteristics that terpenes provide create memorable brand experiences that build consumer loyalty and recognition.

- Pre-Formulated Ratios: The cannabinoid ratios in HTE provide established starting points for product development.

Terpene Belt Farms’ cannabis-derived terpenes deliver similar benefits while eliminating the technical challenges described below. We also provide detailed insights into how specific terpene combinations enhance cannabinoid function.

Technical Limitations and Challenges

Despite its benefits, HTE presents several significant challenges for product manufacturers:

- Viscosity Complications: The high terpene content creates elevated viscosity (typically 30-50 centipoise at room temperature), which can cause clogging in vape hardware and flow issues during manufacturing.

- Shelf-Life Concerns: Terpenes oxidize over time, creating sensory degradation, potentially increasing harmful compounds.

- Regulatory Constraints: The high cannabinoid content (with THC) restricts interstate commerce, complicating multi-state operations. Generally, brands using THC-containing inputs like HTE spend more on compliance management when expanding to new states.

- Batch Consistency: Natural variations in cannabis cultivation create significant batch-to-batch differences in terpene profiles, challenging product standardization.

- Cost Implications: The specialized processing requirements and lower yields make HTE significantly more expensive than other formulation inputs.

These limitations drive manufacturers to seek alternatives that offer HTE’s benefits without the technical complications. Our comprehensive analysis of HTE’s drawbacks explores the underlying challenges in greater detail.

As a practical next step, you can order our Fresh Never Frozen® Sample Packs to see how our cannabis-derived terpenes overcome these issues, delivering the authenticity of cannabis without much hassle.

Cannabis-Derived Terpenes: The Formulator’s Alternative to HTE

For product developers facing HTE’s technical limitations, Terpene Belt Farms’ cannabis-derived terpenes (CDT) offer a compelling alternative without any of HTE’s formulation challenges.

Technical Comparison: HTE vs. TBF CDT

| Parameter | High Terpene Extract | Terpene Belt Farms CDT | Formulation Impact |

| THC Content | 30-50% | 0% | TBF CDT allows interstate shipping and simplified compliance |

| Viscosity | 30-50 cP | 1-5 cP | TBF CDT provides superior hardware compatibility and flow |

| Terpene % | 15-25% | 95-100% | TBF CDT offers precise dosing control in formulations |

| Shelf Stability | 60-90 days | 12-18 months | TBF CDT provides longer product lifecycles and inventory flexibility |

| Batch Consistency | Variable | Standardized ±2% | TBF CDT ensures consistent product experiences |

For formulators, these technical advantages translate to meaningful benefits in manufacturing efficiency, regulatory compliance, and product performance.

Browse our terpene catalog to find the perfect profiles for your product applications.

Implementation in Commercial Formulations

When transitioning from HTE to cannabis-derived terpenes, formulators typically employ one of these approaches:

- Direct Substitution: Replacing HTE with a combination of distillate and cannabis terpenes. Typical formulations use 5-10% terpenes with cannabinoid distillate to mimic HTE’s sensory profile while maintaining optimal viscosity.

- Hybrid Approach: Utilizing CDT to enhance and standardize existing HTE-based formulations. Adding 2-4% cannabis terpenes to HTE can increase sensory impact while improving batch consistency.

- Tiered Product Strategy: Developing multiple product lines using both methodologies, with HTE in premium offerings and CDT-enhanced distillate in mainstream products.

Terpene Belt Farms continues to help manufacturers successfully implement these transition strategies. Our client case studies show reduced product recalls and improved manufacturing efficiency after transitioning to our cannabis-derived terpenes.

Our Standard Oils Sampler provides product developers with multiple terpene profiles to evaluate these formulation techniques with minimal investment. Each sampler includes comprehensive technical documentation and usage recommendations specific to your application.

When to Use HTE vs. Cannabis-Derived Terpenes

Selecting the optimal formulation approach depends on several factors.

Consider HTE When:

- Producing limited-release, premium products where cost is less critical

- Manufacturing in a single state with no expansion plans

- Targeting connoisseur consumers who specifically seek live resin products

- Operating in markets where “full-spectrum” product positioning commands a price premium

Consider Terpene Belt Farms’ Cannabis-Derived Terpenes When:

- Scaling production across multiple states

- Optimizing for hardware compatibility in vape products

- Standardizing product experiences across multiple batches

- Extending product shelf-life and reducing returns

- Maintaining flexibility in inventory management

- Optimizing production costs and margin structure

Terpene Belt Farms provides premium cannabis-derived terpene inputs and the technical expertise to implement them effectively. Our team includes formulation specialists with decades of combined experience in cannabis product development across multiple product categories.

Practical Applications for Product Developers

Product developers considering HTE or cannabis-derived terpenes should evaluate these inputs based on their specific application requirements:

Vape Cartridge Formulation

For vape applications, viscosity and hardware compatibility represent critical considerations. HTE’s high viscosity (30-50 cP) frequently causes clogging issues in many cartridge systems designed for oils in the 8-15 cP range.

Terpene Belt Farms’ cannabis-derived terpenes allow formulators to precisely control viscosity while maintaining authentic cannabis profiles. Our tests show that formulations using our cannabis-derived terpenes experienced fewer hardware failures than HTE-based products, thus getting higher consumer satisfaction scores.

Our vape formulation guide provides specific recommendations for optimizing terpene integration in various hardware systems. For manufacturers seeking to reduce cart failures and consumer complaints, our Premium Oils Sampler includes profiles ideal for vape applications.

Edible Applications

When formulating edibles with terpenes, sensory intensity and consistency become primary concerns. The high concentration of monoterpenes in cannabis-derived terpenes provides a stronger flavor impact at lower usage rates ( 0.1-0.3%) compared to HTE, which requires higher inclusion rates to achieve equivalent sensory impact.

Our formulation protocols explain in detail how to integrate cannabis terpenes into various edible matrices, including gummies, chocolates, and beverages. These protocols address critical considerations like heat stability during production, ingredient interactions, and optimal dosing for balanced sensory profiles.

Topical Product Development

For topical applications, the absence of THC in cannabis-derived terpenes simplifies regulatory compliance while maintaining the functional benefits of terpenes. Research indicates that specific terpenes enhance transdermal penetration, with limonene and pinene particularly effective in increasing active ingredient delivery.

Conclusion: Making the Right Choice for Your Product

HTE is a significant innovation in cannabis processing technology, offering authentic, complex experiences that connect consumers with the complete cannabis profile. However, its technical limitations (e.g., viscosity issues, shelf-life constraints, and regulatory complications) present significant challenges for product manufacturers operating at scale.

Our cannabis-derived terpenes provide a solution to these challenges, delivering authentic cannabis profiles without the regulatory and formulation complications of THC-containing extracts.

By separating terpenes from cannabinoids, our terpene extracts give product developers unprecedented flexibility in formulation while maintaining the unique characteristics that define premium cannabis products.

Our terpenes are processed using proprietary technology that preserves the complete aromatic profile of the original plant material. Thereafter, each batch undergoes comprehensive testing and standardization to ensure consistent performance in all applications.

For product developers ready to experience the benefits of cannabis-derived terpenes in their formulations, our Fresh Never Frozen® Sample Kit offers multiple authentic cannabis profiles for evaluation and testing. Each kit includes comprehensive technical documentation and application recommendations to accelerate product development.

Frequently Asked Questions

What Is High Terpene Extract (HTE)?

HTE is a cannabis concentrate with elevated terpene content (15–25%) designed to preserve the original plant’s aroma, flavor, and effect profile. It usually contains 45–65% cannabinoids.

What Are the Downsides of Using HTE in Products?

HTE is thick (viscous), prone to oxidation, THC-laden (regulatory risk), expensive to produce, and inconsistent batch to batch, making it challenging for scalable, multi-state operations.

How Are Cannabis-Derived Terpenes Different from HTE?

CDTs, like those from Terpene Belt Farms, contain no THC, offer higher terpene concentrations (95–100%), are shelf-stable (12–18 months), and allow consistent, compliant formulation across product lines.

Can CDTs Replicate the Sensory Effects of HTE?

Yes. CDTs can deliver comparable or superior aroma, flavor, and effect profiles through advanced extraction and formulation techniques, especially when strain-specific blends are used.

Which Products Benefit Most from Using CDTs Instead of HTE?

Vape cartridges, edibles, and topicals—where viscosity, shelf life, and regulatory clarity matter, benefit from CDTs in terms of better flow, longer shelf life, and no THC-related shipping restrictions.

Sources Cited:

Gertsch, J., Leonti, M., Raduner, S., Racz, I., Chen, J.-Z., Xie, X.-Q., Altmann, K.-H., Karsak, M., & Zimmer, A. (2008). Beta-caryophyllene is a dietary cannabinoid. Proceedings of the National Academy of Sciences, 105(26), 9099–9104. https://doi.org/10.1073/pnas.0803601105

Lazarjani, M. P., Young, O., Kebede, L., & Seyfoddin, A. (2021). Processing and extraction methods of medicinal cannabis: A narrative review. Journal of Cannabis Research, 3(1). https://doi.org/10.1186/s42238-021-00087-9

Mrunali , P., Kruti , D., & Priti , P. (2021). A Review On Different Extraction Methods of Plants: Innovation from Ancient to Modern Technology. International Journal of Biology, Pharmacy and Allied Sciences, 10(12 (SPECIAL ISSUE)). https://doi.org/10.31032/ijbpas/2021/10.12.1044

Romano, L., & Hazekamp, A. (2013). Cannabis Oil: chemical evaluation of an upcoming cannabis-based medicine. Cannabinoids, 1(1), 1–11. ResearchGate. https://doi.org/https://www.researchgate.net/profile/Arno-Hazekamp/publication/297707359