Quick Answer: Terp spray is a terpene-infused solution applied to cannabis flower through atomization to enhance aroma and flavor profiles. While used in commercial operations for its speed and low cost, terp spray presents significant technical limitations including uneven distribution, surface-level application, terpene degradation during atomization, and inconsistent consumer experiences. Advanced infusion methods offer superior penetration, consistency, and product quality for brands prioritizing premium positioning.

Key Takeaways

- Terp spray is a terpene-infused liquid applied to cannabis flower to enhance aroma and flavor through surface atomization.

- It’s cheap, fast, and widely used to fix low-aroma or low-grade flower, but creates uneven coverage, terpene loss, and inconsistent results.

- Manual and automated spray systems both struggle with dosing accuracy, penetration, and batch-to-batch consistency.

- Technical drawbacks include terpene oxidation, residue from carriers, and only surface-level enhancement rather than full-flower infusion.

- Terpene Belt Farms offers more consistent delivery compared to terp spray with our Fresh Never Frozen™ cannabis terpenes and NEU Bag infusion technology. This technology delivers deep, uniform terpene integration without carriers or equipment. Try out our sample kits today.

You’re facing a familiar problem: batches of cannabis flower that meet safety standards but smell like hay. Or inventory that lacks the aromatic punch consumers expect when they crack open a jar. Your cultivation partner delivered on potency but not on terpene expression, and now you’re stuck deciding whether to accept steep discounts or find a way to salvage the aromatic profile.

This scenario plays out daily across processing facilities, and terp spray is considered a quick-fix solution that promises to turn bland flowers into aromatic products within minutes.

The appeal is obvious. Low equipment costs, minimal training requirements, and rapid application that doesn’t slow down production lines. For processors handling large volumes on tight margins, the economics of spray enhancement seem compelling at first glance. But the technical realities of atomizing terpenes onto flower surfaces create quality trade-offs that extend far beyond the application stage.

While there are better alternatives for more consistent coverage with products like NEU bags, you need to understand exactly what spray-based enhancement can and cannot deliver before committing to a method that will affect consumer experience, repeat purchase rates, and long-term brand reputation.

This article breaks down terp spray from composition through application methods, technical limitations, and quality outcomes. We’ll examine why processors choose spray approaches, identify the specific problems these methods create, and outline precision infusion alternatives that address the fundamental shortcomings of surface-level terpene application.

What is Terp Spray: Composition and Industry Applications

Terp spray represents a category of terpene-infused liquid formulations designed for topical application to cannabis flower through atomization or misting systems.

Unlike precision infusion methods that integrate terpenes throughout plant material, spray applications rely on surface-level deposition to modify aromatic and flavor characteristics of finished flower.

The fundamental concept is straightforward: diluted terpene solutions are applied as fine droplets that coat external flower surfaces, theoretically improving sensory appeal without requiring complex equipment or extended processing time.

Chemical Composition of Commercial Terp Sprays

Commercial terp spray products are isolated or blended terpene compounds suspended in carrier solvents that facilitate atomization and flower surface adhesion. The terpene component itself may originate from cannabis sources, botanical alternatives, or synthetic production, depending on the product tier and target price point.

Cannabis-derived terpenes offer the most authentic aromatic profiles, but the economics of spray applications, where relatively large volumes are required, often drive manufacturers toward less expensive botanical or synthetic alternatives.

Carrier solvents serve multiple functions in spray formulations, including terpene solubilization, viscosity adjustment for optimal atomization characteristics, and surface adhesion promotion. Common carrier options include:

- Ethanol for rapid evaporation and solvent properties

- Propylene glycol for viscosity control and terpene suspension

- Vegetable glycerin for surface adhesion and moisture retention

- Food-grade carrier oils for extended surface contact time

The selection of a carrier system significantly impacts both application performance and potential residue concerns, as these solvents remain on flower surfaces after application and may affect combustion characteristics, flavor perception, or laboratory testing results.

Market Positioning and Target Use Cases

Within the cannabis processing ecosystem, terp spray products occupy a specific niche characterized by particular operational priorities and quality trade-offs. The primary positioning for terp spray centers on the rapid transformation of lower-grade flower inventory into more aromatic products that can command higher retail prices or simply become saleable in quality-conscious retail environments.

Terp spray also finds application in operations attempting to create consistent aromatic experiences across multiple flower sources with naturally variable terpene profiles. In situations where brand consistency matters but cultivation consolidation isn’t feasible, spray applications offer a superficial standardization approach.

A processor sourcing from multiple farms can theoretically apply identical spray formulations to create more uniform aromatic output, though the effectiveness of this approach depends heavily on the underlying flower quality and application precision.

Why Cannabis Processors Turn to Terp Spray Solutions

The widespread adoption of terp spray in commercial cannabis operations reflects pragmatic responses to specific operational and economic pressures facing processors.

While the technical limitations of spray applications are significant, there are some reasons why these products exist and why they’re popular.

Low Upfront Investment and Operating Costs

Economic factors drive many processing decisions, and terp spray systems offer compelling initial cost advantages that appeal to budget-conscious operations. The capital investment required to implement spray-based enhancement is minimal compared to more sophisticated infusion technologies, often requiring nothing more than commercial spray bottles or simple atomization equipment that costs hundreds rather than thousands of dollars.

The ongoing operational costs also appear favorable on surface-level analysis, with minimal labor requirements and low per-unit processing time. Terpene costs themselves also favor spray applications in many product formulations, though this advantage comes with significant quality trade-offs.

Because spray methods rely on inexpensive botanical or synthetic terpene sources rather than premium cannabis-derived options, the raw material costs per batch remain low even when applying relatively large volumes.

Speed and Simplicity in High-Volume Operations

Operational velocity represents another compelling factor driving spray adoption. In facilities handling hundreds or thousands of pounds of flower weekly, processing speed directly impacts throughput capacity and revenue potential.

Spray applications require minimal time investment, often just seconds per unit, allowing rapid enhancement of large batches without creating production bottlenecks. The learning curve for spray application is virtually nonexistent, requiring no specialized training or technical expertise.

Salvaging Lower-Grade Inventory

Perhaps the most honest assessment of terp spray’s role acknowledges its function as an inventory salvage tool for material that would otherwise struggle to find buyers at acceptable prices. Cultivation operations inevitably produce flower batches that meet minimum safety and potency standards but lack the aromatic appeal that consumers expect.

Rather than accepting steep discounts or rendering this material into concentrates, processors apply terp sprays to create superficially acceptable aromatic profiles that enable these batches to move through distribution channels.

Application Methods: How Terp Spray is Used in Commercial Operations

The practical execution of spray-based terpene application varies significantly across processing operations, ranging from rudimentary manual approaches to semi-automated systems designed for higher throughput environments.

Regardless of sophistication level, all spray-based systems share fundamental constraints related to surface-level deposition, atomization variability, and the physical limitations of topical application to complex botanical structures.

Manual Spray Application Techniques

The most common spray application method in small to mid-sized operations involves manual application using commercial spray bottles or small-scale atomizers. Operators typically spread flower material in thin layers on processing tables or trays, then apply terpene spray in multiple passes while attempting to achieve even coverage across all exposed surfaces.

Manual spray techniques require operators to constantly make judgments about application distance, spray angle, solution volume, and coverage adequacy; decisions that directly impact terpene deposition and distribution consistency.

The flower material itself presents significant challenges for manual spray applications. Dense bud structures create shadowed areas that spray cannot effectively reach, leaving interior flower sections largely untreated while external surfaces receive terpene deposition.

Automated Spray Systems for Scale Production

Higher-volume operations sometimes implement semi-automated spray systems that attempt to standardize application parameters and reduce operator variability. These systems typically involve conveyor belts or rotating drums that move flower material through spray zones where fixed atomization nozzles apply terpene solutions at predetermined rates.

Automated spray systems must solve complex engineering challenges related to spray pattern optimization, solution delivery consistency, and flower handling without causing structural damage.

The atomization nozzles require precise calibration to generate appropriate droplet sizes. They should be small enough to coat flower surfaces effectively but large enough to avoid excessive evaporation before deposition.

Dosing and Coverage Challenges

Regardless of application method sophistication, spray-based enhancement faces fundamental dosing challenges that stem from the inherent variability of topical application to complex botanical structures. Unlike precision infusion methods that can deliver precisely measured terpene quantities throughout flower material, spray applications rely on statistical averaging across large batches to approximate target dosing levels.

The industry lacks standardized protocols for calculating or verifying actual terpene deposition from spray applications. Processors normally work with volume-based metrics, applying a certain quantity of spray solution per pound of flower, but these measurements provide no insight into actual terpene transfer efficiency or distribution consistency.

Technical Limitations of Spray-Based Terpene Application

Moving beyond operational considerations into fundamental technical analysis reveals the inherent constraints that make spray-based terpene application unsuitable for premium product formulations or brands prioritizing consistent consumer experiences.

These limitations stem from the basic physics of topical liquid application to complex botanical structures and the chemical realities of terpene behavior during atomization and surface deposition.

Surface-Level Distribution vs. Penetration

The most fundamental limitation of spray-based terpene application is its inability to achieve meaningful penetration into flower structures. Spray droplets impact external surfaces but cannot overcome the physical barriers of densely packed calyxes and trichomes. The terpene compounds remain where they first contacted the flower, creating superficial coating rather than integrated distribution.

This surface-level concentration creates predictable consumer problems. Initial aromatic impact can be impressive, but as consumers break apart flower material, they encounter interior portions with minimal enhancement. Aromatic intensity drops precipitously as surface-deposited terpenes disperse and bland interior material becomes exposed.

Terpene Degradation During Atomization

The atomization process subjects terpene compounds to physical stresses that accelerate degradation. Many spray systems generate heat as a byproduct, which is problematic for volatile compounds like limonene and pinene, which degrade readily at elevated temperatures.

Atomization also dramatically increases the surface area exposed to oxygen, accelerating oxidation reactions that create off-flavors. As the spray solution disperses into thousands of droplets, each presents a fresh terpene-air interface where oxidation occurs before the droplets contact flower surfaces. This degradation continues after deposition and worsens during storage.

Inconsistent Batch-to-Batch Results

Perhaps the most problematic technical limitation of spray-based enhancement is the inherent batch-to-batch variability that makes consistent product quality difficult to achieve, regardless of operator skill or equipment sophistication. This inconsistency stems from the cumulative effect of multiple uncontrolled variables in the spray application process.

Flower material heterogeneity represents a primary source of consistency challenges. Even flowers from the same cultivar and cultivation batch exhibit natural variations in bud density, size distribution, moisture content, and surface characteristics that affect how spray deposition occurs and how applied terpenes interact with flower structures.

Carrier Solvent Residue Concerns

The carrier solvents required for spray application introduce residue concerns that many processors fail to address adequately in their quality control protocols. While these solvents may be food-grade or generally recognized as safe for consumption, their presence in final products affects flavor characteristics, combustion properties, and consumer perception in ways that can significantly impact product quality.

Propylene glycol and vegetable glycerin, common carriers in spray formulations, do not fully evaporate after application, instead remaining on flower surfaces where they alter combustion characteristics and create flavor notes that consumers often perceive negatively. When heated during smoking or vaporization, these carriers can produce harsh throat sensations and chemical flavors that mask the terpene characteristics they were intended to deliver.

Alternative Approaches: Precision Infusion Methods for Commercial Scale

For processors seeking to improve flower quality without the technical limitations and quality inconsistencies of spray applications, precision infusion methods represent a fundamentally superior approach to terpene integration. Here’s how we can help:

Deep-Penetration Infusion Technology

Terpene Belt Farms’ Fresh Never Frozen infusion technology exemplifies the capabilities of precision enhancement methods. Rather than surface atomization, controlled-environment infusion allows terpenes to penetrate flower structures through regulated temperature, humidity, and time parameters that promote absorption without degradation. The result is even terpene distribution from exterior surfaces through interior calyxes, delivering the predictable experience that consumers expect from premium products.

Deep-penetration infusion technology addresses the fundamental shortcoming of spray applications by working with flower material in conditions where terpene compounds can migrate into bud structures rather than remaining concentrated on external surfaces.

This approach involves placing flowers in sealed chambers where temperature, humidity, and atmospheric composition are carefully controlled to promote terpene absorption while preventing degradation.

Terpene Oil Product Recommendations

Terpene Belt Farms offers a comprehensive selection of Fresh Never Frozen cannabis terpene profiles designed for commercial-scale enhancement.

Our 2024 Fruit collection delivers bright, tropical aromatic profiles, while Gas-forward profiles provide the pungent, fuel-like characteristics consumers associate with premium flower.

For product developers seeking aromatic diversity, our Flavor Profile Oils Sampler provides exposure to multiple terpene expressions across categories, including dessert, purple, and pine profiles, allowing formulation testing without committing to large-volume purchases.

NEU Bags

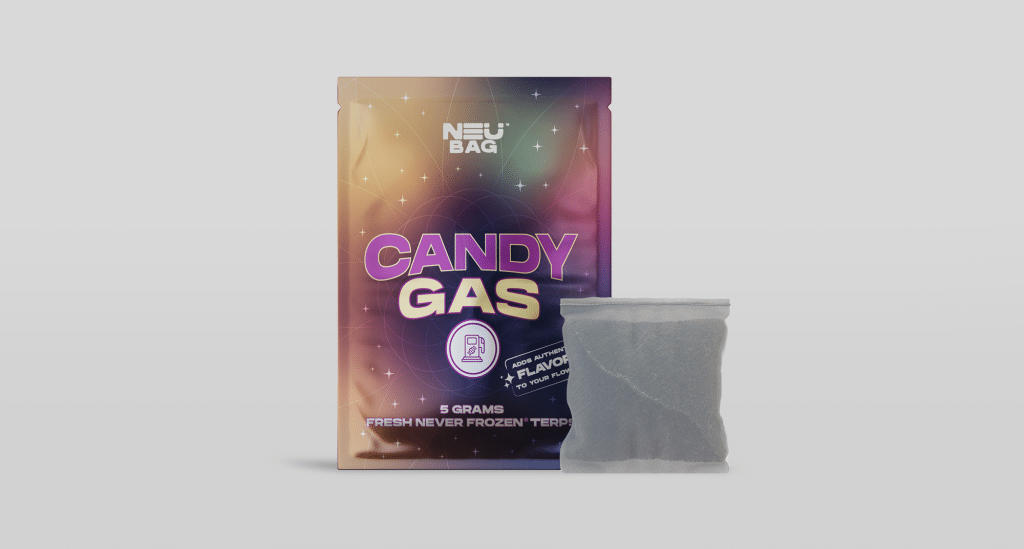

For formulators looking for equipment-free infusion solutions, Terpene Belt Farms’ NEU Bag technology provides an innovative alternative to both spray methods and complex machinery.

NEU Bags utilize natural diffusion to migrate Fresh Never Frozen cannabis terpenes from mesh infusion packs directly into flower structures over 48 hours. Independent testing by Fernway’s R&D team confirmed 4.18% terpene content increases with uniform distribution throughout flower material, results that spray application cannot achieve. The process requires no specialized equipment, simply placing one NEU Bag per pound of flower in

NEU Bags Product Recommendations

Operations can begin with our 5 NEU Bag Terpene Sample Kit to test the diffusion infusion process across multiple flavor profiles before scaling. For production runs, profile-specific packs like Gas Infusion Pack and Dessert Infusion Pack are available in quantities from 30g up to 1,250g to match batch sizes.

The Candy Gas NEU Bag has proven particularly popular with processors enhancing mid-grade flower destined for pre-roll applications, delivering the sweet, fuel-forward aromatic profile that moves products quickly in competitive retail environments.

Looking to improve your product line with terpenes the right way? Get sample kits from Terpene Belt Farms to experience the difference authentic cannabis-derived terpenes make in final product quality.

Frequently Asked Questions About Terp Spray

What Is Terp Spray Made Of?

Terp spray consists of terpene compounds (from cannabis, botanical, or synthetic sources) dissolved in carrier solvents like ethanol, propylene glycol, or vegetable glycerin. The specific formulation varies by manufacturer, but all terp sprays require carrier solvents to achieve the liquid consistency needed for atomization and application to flower surfaces.

Is Terp Spray Safe to Use on Cannabis?

While terp spray ingredients are generally food-grade and considered safe for consumption, the application method creates several concerns. Carrier solvent residues remain on flower surfaces and may produce harsh flavors or throat irritation during consumption. Additionally, the uneven distribution and surface concentration of sprayed terpenes can create inconsistent consumer experiences that affect product perception and satisfaction.

How Can I Tell if My Weed Is Sprayed With Terps?

Several indicators suggest spray treatment: unusually strong initial aroma that fades quickly upon air exposure, aromatic intensity that drops significantly when buds are broken apart, matted or clumped trichome structures visible under magnification, unnatural surface sheen from carrier residue, and simplified single-note aromatic profiles rather than complex cannabis characteristics. Laboratory testing can definitively identify spray treatment through carrier solvent detection and terpene profile analysis.

Does Terp Spray Get You High?

No, terp spray does not produce intoxication effects. Terpenes are aromatic compounds that influence flavor and potentially modulate cannabis effects, but they do not cause euphoria or altered consciousness on their own. The intoxication from cannabis comes from cannabinoids like THC, not from terpenes, whether naturally occurring or spray-applied.

What’s the Difference Between Terp Spray and Terpene Infusion?

Terp spray applies terpenes topically through atomization, creating surface-level enhancement that cannot penetrate into flower structures. Precision terpene infusion uses controlled-environment processes to integrate terpenes throughout flower material, achieving even distribution and consistent consumer experiences. Infusion methods deliver superior quality, shelf stability, and aromatic consistency compared to spray applications.

Are There Better Alternatives to Terp Spray for Cannabis Enhancement?

Yes, precision infusion technologies like Terpene Belt Farms’ Fresh Never Frozen process offer dramatically superior results for brands prioritizing quality and consistency. These methods achieve deep terpene penetration throughout flower structures using authentic cannabis-derived terpene profiles, delivering reliable consumer experiences and premium product positioning that spray applications cannot match.

Can Terp Spray Damage Cannabis Flower?

Heavy spray application can damage delicate trichome structures through carrier solvent interaction and mechanical forces during application. The rapid evaporation of some carrier solvents also creates localized cooling that can stress flower tissue. Additionally, spray carrier solvents may dissolve some naturally occurring compounds, potentially reducing rather than enhancing overall flower quality depending on application technique.