There are several terpene infusion methods, ranging from passive vapor-phase transfer systems to active spray application, with success metrics being, but not limited to, terpene retention rates, distribution uniformity, and preservation of visual quality.

Other methods include bucket systems, remediation boxes, small batch packets, premium strain-specific devices, industrial equipment, and direct spray application. Selecting the right method depends on terpene source quality, integration efficiency, cost per pound, and preservation of flower integrity.

The primary challenge in terpene infusion is achieving uniform distribution while preserving the structural integrity of cannabis flower and the chemical complexity of terpene profiles. NEU Bags are the most balanced solution for commercial operations, achieving 85-95% terpene transfer efficiency at $0.50 – $2.00 per pound treated.

Here is an analysis of commercially available terpene infusion solutions based on performance metrics, cost analysis, and practical implementation considerations for B2B cannabis operations.

Key Takeaways

- NEU Bags achieve 85–95% transfer efficiency with whole-plant terpenes while preserving flower structure and appearance, processing unlimited quantities in parallel with minimal labor, and maintaining low costs.

- Bucket and spray systems are limited by scalability, cost, and quality risks.

- Industrial remediation systems can add excessive moisture, leading to microbial risks and visual degradation (darkening and trichome rupture), which can lower product quality and wholesale value despite processing efficiency.

- Large-scale industrial infusion is ideal for operations processing 5,000+ pounds monthly due to hidden costs and maintenance needs, making it impractical for smaller producers.

What Makes a Good Terpene Infusion System?

Successful terpene infusion requires balancing multiple technical and economic factors that directly impact product quality and operational efficiency. Our evaluation framework examines each solution across standardized metrics relevant to commercial cannabis operations, particularly on scalability, consistency, and preservation of flower integrity.

Transfer efficiency is undoubtedly the primary technical metric. It measures the percentage of terpenes migrating from the source to the flower. Industry standards expect a minimum 80% retention to justify processing costs.

Distribution uniformity, measured through the coefficient of variation across multiple sampling points, determines consumer experience consistency. Processing time directly impacts facility throughput, while terpene source quality affects product positioning and regulatory compliance.

| Evaluation Criteria | Measurement Method | Industry Standard | Impact on Operations |

| Transfer Efficiency | GC-MS pre/post analysis | >80% retention | Direct cost impact |

| Distribution Uniformity | 5-point sampling variance | <10% CV | Consumer consistency |

| Processing Time | Hours to completion | 24-72 hours | Throughput capacity |

| Terpene Source Quality | Whole plant vs. botanical | Strain-specific | Product positioning |

| Cost per Pound | Total cost/pounds treated | $2-40/lb | Margin impact |

Cost analyses usually factor in more than equipment investment and consider labor requirements, material losses, and quality impacts. Generally, high-volume operations processing thousands of pounds monthly require different solutions than craft producers handling smaller batches.

The right solution balances these factors based on specific operational parameters and market positioning goals.

NEU Bags: How Vapor-Phase Integration Works

NEU Bags represent a passive vapor-phase transfer system utilizing mesh containers saturated with whole plant cannabis extracts. The technology uses natural vapor pressure differentials to migrate terpenes from the carrier to the flower over controlled periods, eliminating the need for specialized equipment or complex procedures.

Technical Performance Data

The system operates through controlled vapor-phase diffusion, with terpenes migrating based on concentration gradients between the saturated mesh and the surrounding flower.

Laboratory tests show 85-95% transfer efficiency when proper protocols are followed, with final flower analyses showing 1-3% total terpene improvement depending on application rate and starting material characteristics. This efficiency rate exceeds most mechanical methods and minimizes material losses associated with spray application.

Operational parameters important for success:

- Temperature range: 60-75°F for ideal vapor pressure

- Humidity: 55-62% RH prevents over-drying

- Container specifications: Sealed, food-grade materials

- Scaling capacity: Unlimited through parallel processing

- Terpene source: Whole plant Cannabis sativa L extracts

Why NEU Bags Cost Less Per Pound

Our cost analyses demonstrate clear economic advantages, particularly at commercial scale. Bag pricing ranges from $15 to $60, depending on size and terpene profile complexity. The cost per pound treated is between $0.50 and $2.00 based on flower quantity and desired improvement level.

This positions NEU Bags as the most economical solution for operations processing 100 or more pounds monthly, with costs decreasing further at higher volumes through bulk purchasing options.

The main advantage of NEU Bags is the complete preservation of flower structure and visual quality. Unlike liquid application methods that often damage trichomes or add unwanted moisture, vapor-phase transfer maintains the flower’s original appearance and achieves uniform terpene distribution.

Our quality tests show terpene levels within 8% variance across random sampling points when proper turning protocols are followed during the integration period.

The 48-hour minimum transfer time represents the primary operational constraint. However, this passive approach enables the simultaneous processing of unlimited quantities, offsetting time requirements through parallel processing capacity. Operations can treat 10 or 10,000 pounds easily by using more NEU Bags and containers.

Further, classifying terpenes as aromatic products rather than ‘machinery’ simplifies customs clearance and reduces regulatory barriers for international operations. This provides compliance advantages in markets with complex cannabis regulations.

Bucket Systems: Mid-Range Solutions with Limitations

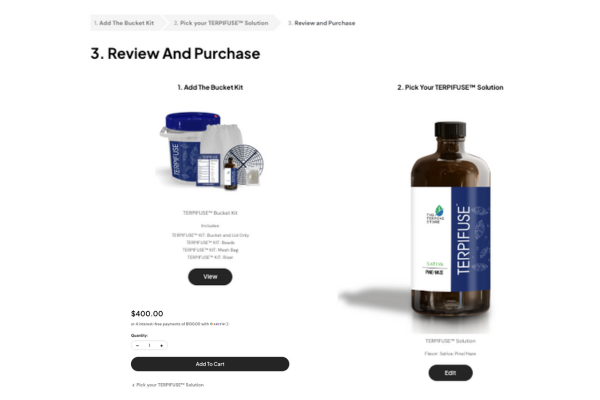

Bucket-based infusion systems are an intermediate approach between small-batch methods and industrial equipment. These systems typically utilize specialized containers with controlled environments for terpene application. They are marketed with capacities ranging from 2 to 10 pounds per cycle.

However, technical evaluations reveal operational constraints that impact commercial viability.

Real Capacity vs. Marketing Claims

The main issue of bucket-based infusion systems is actual versus marketed capacity. While promotional materials may claim 10-pound daily processing, achieving this throughput requires multiple 2-pound cycles, creating labor intensity that scales poorly.

Each cycle requires 30-45 minutes of active labor for loading, unloading, and system preparation, resulting in 2.5 to 4 hours of labor per 10 pounds processed. This linear scaling of labor requirements makes bucket systems uneconomical for operations exceeding 50 pounds daily.

The equipment cost positions this method in the mid-tier cost category. However, the initial investment provides only basic functionality and lacks advanced features like automated mixing, temperature control, or vapor recovery, like professional-grade equipment.

The cost per pound capacity based on equipment alone can hit hundreds of dollars, before factoring in terpene costs, labor, and operational overhead.

Botanical Terpene Restrictions

For quality-focused brands, bucket systems often restrict users to botanical terpene options, typically offering 15-25 pre-formulated profiles. The exclusive use of botanical terpenes limits product positioning, as gas chromatography analyses reveal botanical profiles contain much less cannabis compounds than whole plant cannabis extracts.

Moreover, custom profile development, when available, often incurs additional costs that further erode economic viability.

Processing time is another operational challenge, with most bucket systems requiring 2-4 days for complete infusion. The prolonged timeline and limited batch capacity create throughput bottlenecks for growing operations. Unlike passive systems, bucket systems cannot process multiple batches simultaneously, compounding these capacity constraints.

Industrial Remediation: When Moisture Becomes a Problem

Large-scale remediation systems promise to address terpene improvement and microbial reduction in a single process. These industrial solutions target high-volume operations with automated processing capabilities. However, our analyses reveal quality concerns that warrant careful evaluation before implementation.

Moisture Addition and Quality Degradation

The primary concern during the remediation is moisture addition. Laboratory analyses of flower processed through these systems consistently show moisture content increases of 8-15%, pushing final moisture levels well above safe storage parameters. This creates cascading quality issues that extend beyond material weight gain.

Water activity measurements reveal concerning results. Starting material is typically maintained at 0.55 aw for stability, but often exits these systems at 0.65 aw or higher, exceeding the 0.60 threshold at which microbial proliferation accelerates. The elevation in water activity negates the microbial reduction benefits, creating conditions favorable for rapid recontamination during storage.

Visual and Physical Damage

Visual quality degradation presents immediate commercial challenges. The combination of heat, moisture, and processing time darkens flower material, with L* color values dropping 15-25 points on standardized measurements. This darkening, readily apparent to consumers, typically results in a substantial wholesale price reduction.

Microscopic examinations reveal extensive trichome damage, with glandular heads showing rupture rates >30% in processed samples. This physical damage not only impacts visual appeal but also alters cannabinoid and terpene availability, changing the product’s effect profile.

The combination of moisture addition, color degradation, and trichome damage can transform premium flower into mid-grade products, affecting profit margins despite the promise of increased yields through remediation.

Small-Batch Solutions: Why They Don’t Scale

Packet-based terpene delivery systems target micro-batch applications, typically for personal use or sample preparation. These products utilize controlled-release technology similar to humidity control packets, promising reusable applications for small quantities of flower.

Mathematical Impossibility of Scaling

Technical evaluations reveal constraints that restrict commercial viability. Maximum capacity constraints of 14 grams per packet create scaling challenges for commercial operations. Processing even a single pound would require 32 packets, making this approach economically and logistically impractical beyond sample preparation or consumer retail applications.

The limitation to single isolated terpenes rather than complex profiles restricts improvement capabilities. Products offering isolated terpenes cannot effectively recreate the synergistic effects achieved through whole plant profiles. Indeed, isolated terpenes cannot replicate the entourage effect created by dozens of compounds working together within authentic cannabis extracts.

Product specifications often lack important technical details, particularly regarding release rates and target concentrations. Without defined dosing parameters, achieving reproducible results across multiple applications is difficult.

This uncertainty, combined with limited reusability of only three cycles, results in costs exceeding $200 per pound when scaled to commercial quantities. The absence of analytical data supporting marketing claims further undermines confidence in consistent performance.

Premium Devices: High Cost, Low Transparency

Premium-positioned devices marketed for strain-specific improvement command high prices. These products emphasize convenience and proprietary formulations but often lack published technical specifications for commercial evaluation.

Missing Technical Data

The absence of basic technical data creates evaluation challenges for commercial operators. Capacity specifications remain unpublished, though product dimensions suggest suitability for 14-28 gram quantities.

Transfer mechanisms appear to utilize passive diffusion similar to other packet systems, but without published efficiency data, performance remains speculative. Terpene concentrations, application protocols, and analytical verification of strain matching claims are notably absent from available documentation.

These devices represent the highest cost-per-gram solution in the market. Scaling to larger quantities would require higher costs, making them suitable only for ultra-premium positioning where price sensitivity doesn’t matter. The lack of technical specifications affects accurate ROI calculations, while the absence of third-party analytical data leaves performance claims unverified.

Marketing emphasis on strain-specific profiles lacks supporting analytical data demonstrating actual similarity to claimed cultivars. Product claims cannot be substantiated without gas chromatography comparisons between device output and authentic strain profiles.

Moreover, the absence of technical validation and premium pricing positions these devices outside practical consideration for commercial operations requiring predictable, verifiable results.

Industrial Machinery: When Does Automation Make Sense?

Industrial terpene infusion machinery represents the high-volume automation approach, with equipment investments starting at $110,000 and escalating based on capacity and features. These systems promise rapid processing and minimal labor requirements for large-scale operations.

Breaking Down the Real Costs

Financial analyses reveal barriers to implementation beyond initial capital requirements. Equipment costs are only the beginning, with installation, facility modifications, and training potentially adding 20-30% to the total investment.

Further, maintenance contracts, replacement parts, and technical support create ongoing operational expenses that must be factored into total cost of ownership calculations.

Return on investment calculations demonstrate the volume requirements for economic viability. Assuming $5-10 per pound operational cost and 20% of product value allocated to terpene improvement, break-even requires processing approximately 5,000 pounds monthly.

This calculation assumes no equipment downtime, consistent throughput, and stable market prices. Operations below this volume threshold cannot justify the investment regardless of technical capabilities.

Documentation Gaps

Limited technical documentation can prevent a detailed performance evaluation. While marketing materials emphasize speed and capacity, important specifications remain unpublished.

Transfer efficiency rates, distribution uniformity data, and quality preservation metrics—basic parameters for evaluating any infusion technology—are notably absent. The lack of detailed technical data raises concerns for operations considering six-figure investments without the ability to validate performance claims.

Maintenance and operational complexity introduce additional risk factors. Industrial equipment requires trained operators, regular maintenance schedules, and rapid access to technical support.

Equipment downtime directly impacts production capacity, with each day of non-operation representing thousands in lost processing capability. These factors must be weighed against the promised benefits of automation.

Direct Spray Methods: Simple but Problematic

Direct spray application using pneumatic guns or manual sprayers is the most straightforward technical approach to terpene infusion. This method requires minimal equipment investment but faces technical limitations that impact commercial viability.

Distribution and Waste Issues

Distribution uniformity is the primary technical challenge with spray application. Even experienced operators struggle to achieve consistent coverage across three-dimensional flower surfaces.

Laboratory analyses of spray-treated samples typically reveal a coefficient of variation >25% between sampling points, far above the 10% threshold for acceptable uniformity. This creates inconsistent consumer experiences and potential hot spots where terpene concentration exceeds pleasant or safe levels.

Material losses through overspray dramatically impact process economics. Testing across multiple operators and equipment types shows 30-50% of sprayed material failing to contact the target flower, instead coating equipment surfaces or becoming airborne.

These losses effectively double or triple the per-pound terpene cost, often costing $10-20 per pound when accounting for wasted material.

Physical Impact on Flower

Direct liquid contact creates additional quality concerns. Microscopic examination reveals trichome damage at spray contact points, with glandular heads showing mechanical disruption from droplet impact.

This physical damage alters the release characteristics of both native and added terpenes. Moisture addition from liquid carriers can elevate water activity, while uneven distribution creates areas of oversaturation that may develop differently during storage.

Labor intensity scales linearly with volume, making spray methods increasingly impractical as operations grow. Each pound requires individual handling and careful application to minimize variation, with no opportunity for parallel processing or automation.

Worker safety concerns also emerge at scale, as repeated exposure to aerosolized terpenes necessitates ventilation and personal protective equipment.

How Much Does Each Method Cost?

Understanding true operational costs requires analyses beyond equipment pricing. Total cost of ownership must incorporate equipment amortization, labor requirements, material losses, and quality impacts that affect final product value.

| Solution | Equipment Cost | Cost per Pound | Terpene Type | Quality Impact | Scaling Efficiency |

| NEU Bags | $0 | $0.50-2.00 | Whole Plant | None | Excellent |

| Bucket Systems | $400-800 | $40+ | Botanical Only | Minimal | Poor |

| Remediation Box | Varies | High+Moisture | Variable | Major | Good |

| Packet Systems | $30/3-pack | $200+ | Isolated | None | Very Poor |

| Premium Devices | $79+ | $280+ | Unknown | Unknown | Very Poor |

| Industrial | $110,000+ | $5-10 | Unknown | Unknown | Excellent |

| Spray | $200-2000 | $10-20 | Any | Moderate | Poor |

NEU Bags demonstrate better economics by minimizing equipment costs and reducing labor requirements. The ability to process unlimited quantities simultaneously via parallel processing provides unmatched scaling efficiency. Preserving flower quality ensures no value degradation, while whole plant terpene options support premium positioning.

Mid-tier solutions like bucket systems are largely uneconomical due to limited capacity and high labor requirements. The restriction to botanical terpenes further limits market positioning options, making it difficult to justify the investment for most operations. Only facilities with specific niche requirements find these systems economically viable.

Industrial solutions require massive scale to achieve reasonable per-pound costs. The break-even analysis demonstrates that operations processing less than 5,000 pounds monthly cannot justify automation investments. This reality limits industrial equipment to the largest multi-state operators or processing facilities.

Best Practices for Any Terpene Infusion Method

Successful terpene infusion at commercial scale requires systematic approaches to material preparation, process control, and quality verification. These practices apply regardless of chosen technology but are particularly important when implementing passive systems where environmental control replaces mechanical precision.

Pre-Treatment Requirements

Material qualification forms the foundation of consistent results. Moisture content verification ensures starting material falls within ideal ranges, typically 8-10% for flower products.

Baseline terpene profiling through GC-MS analysis establishes improvement targets and enables verification of successful integration. Visual quality documentation provides reference standards for comparison post-treatment, while microbial testing may be required depending on regulatory requirements and the chosen method.

Process Control Standards

Process standardization ensures batch-to-batch consistency regardless of operator variability. Environmental monitoring systems should track temperature and humidity throughout integration periods, with defined acceptable ranges based on validated parameters.

Standard operating procedures must detail every step from material preparation through final packaging, with clear decision points for quality control interventions. Batch documentation creates traceability and enables continuous improvement through data analysis.

Quality Verification Methods

Quality verification validates successful integration and ensures the product meets specifications before release. Multi-point sampling protocols should define minimum sampling locations based on batch size, with acceptance criteria for variation between points.

Analytical testing confirms total terpene improvement and profile preservation, which are particularly important when using whole plant extracts. Sensory evaluation by trained panels provides qualitative validation that analytical data alone cannot capture, while stability testing projects shelf life under various storage conditions.

State Regulations and Compliance Requirements

Terpene infusion must comply with evolving state-specific regulations. Understanding compliance requirements prevents costly violations while ensuring market access for improved products.

Documentation and Testing

Documentation requirements typically begin with source material verification for both flower and terpenes. Certificates of analysis must demonstrate compliance with applicable standards, including potency, pesticides, and microbial parameters.

Process documentation requirements vary but generally include batch records, equipment logs, and quality control data. Final testing requirements often exceed those for non-enhanced flower, with some states mandating terpene profiling or residual solvent testing.

Terpene Source Restrictions

Terpene source restrictions represent an emerging regulatory trend with operational impact. Several medical markets restrict improvement to cannabis-derived terpenes only, eliminating botanical options regardless of safety profiles.

Adult-use markets generally permit food-grade botanical terpenes, though this may change as regulations evolve. Synthetic terpenes face increasing prohibition, with several states explicitly banning their use in cannabis products.

Labeling requirements for improved products continue to develop across markets. For example, California requires disclosure of added terpenes on labels, while Colorado mandates specific language for any post-harvest additions.

Some markets require differentiation between cannabis-derived and botanical sources, creating additional complexity for multi-state brands. As such, understanding local requirements during product development prevents costly labeling revisions or market exclusions.

What Do Consumers Want?

Choosing between terpene infusion methods transcends technical specifications to encompass market positioning and consumer preferences. Understanding these dynamics helps align technology selection with brand strategy and target demographics.

Premium Market Expectations

Premium market segments increasingly demand authenticity and transparency. Consumers who know about terpenes easily recognize the difference between whole plant profiles and botanical alternatives, and generally prefer products with cannabis-derived terpenes. This trend particularly impacts markets with mature consumer bases prioritizing effect consistency over price considerations.

Value-conscious segments may accept botanical terpenes if priced appropriately, but still expect quality flower. Methods that add moisture or visibly alter flower appearance are not readily accepted, regardless of price point. This creates opportunities for technologies that improve flower without compromising visual appeal or smoking characteristics.

Transparency Builds Trust

Transparency in improvement methods increasingly influences purchasing decisions. Brands that communicate their technology and terpene sources build trust with informed consumers. This transparency extends to providing analytical data demonstrating successful integration and profile authenticity. Methods compatible with clean, simple messaging gain market advantages over complex or opaque technologies.

Future Technology Developments

Terpene infusion methods continue to change with emerging technologies reshaping current approaches. Understanding these new trends helps brands plan for future capabilities while avoiding premature investment in unproven methods.

Emerging Technologies

Encapsulation technologies show promise for protecting volatile terpenes during storage and handling. Microencapsulation could enable more stable, concentrated delivery systems that release terpenes through specific triggers like temperature or pressure. However, regulatory acceptance and consumer perception of encapsulated additives remain uncertain, limiting near-term commercial viability.

Ultrasonic and other energy-assisted integration methods may reduce processing times while improving distribution uniformity. Preliminary tests suggest potential for rapid, room-temperature integration to preserve terpene integrity. While these technologies require development before reaching commercial readiness, they warrant monitoring for future implementation.

Analytical Advances

Advances in analytical science continue improving our understanding of terpene behavior and integration parameters. Real-time monitoring capabilities could enable dynamic process adjustment based on actual terpene migration rates.

Advanced analytical methods like 2D gas chromatography can detect previously undetected compounds, helping to differentiate whole plant extracts from simplified alternatives.

Making the Right Choice for Your Operation

Successful commercial terpene infusion requires careful alignment between operational scale, quality standards, and economic constraints. Technical analyses reveal clear performance hierarchies across available solutions, with selection criteria dependent on specific business requirements.

NEU Bags are practical for most commercial operations because they offer low operational cost, high transfer efficiency, and complete preservation of flower quality. The passive vapor-phase approach scales infinitely via parallel processing and maintains product integrity better than other methods. The availability of whole-plant cannabis extracts provides authenticity that botanical-based systems cannot match.

Operations requiring faster turnaround may consider spray application despite poor distribution uniformity and high material losses. This approach serves specific niches where time constraints override quality considerations, though the linear scaling of labor limits viable applications.

Industrial solutions serve only the highest-volume operations where automation justifies capital investment. Facilities processing less than 5,000 pounds monthly cannot achieve a reasonable ROI regardless of technical capabilities. The lack of detailed technical specifications for most industrial systems further complicates evaluation.

The most crucial factor, regardless of the chosen infusion method, is terpene source quality. Solutions limited to botanical or isolated terpenes cannot match the complexity and authenticity of whole plant cannabis extracts. Brands seeking to differentiate through genuine cannabis experiences should prioritize solutions compatible with full-spectrum terpene profiles.

If you are ready to implement professional terpene infusion in your operation, request samples of NEU Bags to test vapor-phase integration. Alternatively, check out our complete NEU Bag Infusion Packs to find the ideal profile for your product.

Frequently Asked Questions

What Is the Most Cost-Effective Terpene Infusion Method for Commercial Cannabis Operations?

NEU Bags provide the lowest cost per pound, requiring no equipment investment. The passive vapor-phase transfer system scales infinitely through parallel processing, making it ideal for operations from 10 to 10,000+ pounds monthly. Factoring in labor, equipment amortization, and material losses, NEU Bags cost 70-95% less than alternative methods.

How Long Do Different Terpene Infusion Methods Take to Complete?

Processing times vary across methods. NEU Bags require 48-72 hours for complete vapor-phase transfer, bucket systems need 2-4 days, including multiple loading cycles, industrial systems complete in 2-4 hours, and direct spray takes minutes but requires additional drying time. The passive methods achieve superior distribution uniformity despite longer processing times.

What’s the Difference Between Botanical and Cannabis-Derived Terpenes for Infusion?

Cannabis-derived terpenes contain more compounds in strain-specific ratios, including trace elements contributing to the entourage effect. Botanical terpenes typically contain fewer compounds and lack the authenticity of cannabis profiles. This difference impacts both sensory characteristics and potential physiological effects of improved products.

How Can I Verify Successful Terpene Infusion Across My Flower Batch?

Implement 5-point sampling from different batch locations, analyzing via GC-MS or GC-FID for terpene content. For acceptable uniformity, target a coefficient of variation below 10% between samples. Additionally, conduct sensory evaluations with trained panels and document visual quality. Successful infusion shows consistent improvement without moisture addition or trichome damage.

Which Terpene Infusion Method Best Preserves Flower Quality?

Vapor-phase methods like NEU Bags preserve flower integrity by avoiding direct liquid contact and moisture addition. The passive transfer maintains trichome structure, prevents color degradation, and adds no moisture that could elevate water activity. Methods involving liquid application or moisture addition show quality degradation under microscopic analysis.

Source Cited

Christensen, C., Rose, M., Cornett, C., & Allesø, M. (2023). Decoding the Postulated Entourage Effect of Medicinal Cannabis: What It Is and What It Isn’t. Biomedicines, 11(8), 2323. https://doi.org/10.3390/biomedicines11082323